Warehouse Monitoring

AI-driven Warehouse Intelligence provides real-time visibility into material movement, vehicle flow, and overall operational efficiency. The system tracks material transfer across zones, monitors loading and unloading activities, and analyzes turnaround times to identify bottlenecks and delays. It ensures adherence to safety procedures by detecting unsafe behavior, PPE non-compliance, and high-risk movements. Forklift traffic is continuously monitored to prevent collisions, optimize routes, and enhance worker safety. By combining movement analytics, process monitoring, and safety oversight, the solution transforms warehouse operations into a smarter, safer, and more efficient environment.

Intelligent Material Flow Tracking System

A large warehouse facility struggled to track real-time material flow across storage zones, staging areas, and dispatch points. Manual logs and worker supervision often led to misplaced items, delayed order processing, and lack of visibility in high-volume environments. These inefficiencies increased operational delays, error rates, and overall supply chain disruption.

The organization implemented an AI-powered Material Movement Tracking System that uses intelligent video analytics to monitor every material transfer, pallet shift, and zone-to-zone movement. Real-time tracking ensures accurate inventory flow, reduces search time, and improves process reliability across warehouse floors.

- Real-Time Material Flow Visibility

- Zone-to-Zone Tracking Alerts

- Reduced Handling Errors & Delays

Business Impact

- ✓Improved order accuracy and reduced material misplacement.

- ✓Faster movement tracking boosts warehouse productivity.

- ✓Increased operational transparency with automated movement logs.

Business Impact

- ✓Faster and more efficient loading/unloading cycles.

- ✓Reduced human supervision effort and operational delays.

- ✓Improved logistics planning with automated insights.

Smart Loading & Unloading Activity Monitoring System

The warehouse faced frequent delays and mismanagement during loading and unloading operations. Manual supervision could not track vehicle alignment, operator performance, or workflow completion, leading to bottlenecks, safety risks, and inconsistent turnaround times.

The organization deployed an AI-driven Loading & Unloading Monitoring System that continuously observes docking zones, workflow progress, and vehicle movements. Automated alerts help supervisors manage efficiency, ensure process accuracy, and maintain safe loading conditions.

- Real-Time Docking Zone Monitoring

- Operator Workflow Visibility

- Process Error & Delay Detection

AI-Based Loading/Unloading Time Efficiency System

High variability in loading and unloading duration caused delays in truck turnaround, order dispatching, and warehouse workflow management. Manual time tracking was prone to inaccuracy, making it difficult to optimize operations and ensure timely movement.

The facility adopted an AI-enabled Time Optimization System that automatically records loading and unloading durations using video analytics. The system identifies inefficiencies, detects idle time, and provides actionable insights to improve turnaround speed and resource planning.

- Automated Time Capture for Each Operation

- Idle Time & Delay Identification

- Enhanced Turnaround Time Management

Business Impact

- ✓Reduced vehicle idle time and improved throughput.

- ✓Enhanced scheduling accuracy for inbound and outbound logistics.

- ✓Stronger process efficiency with data-driven time insights.

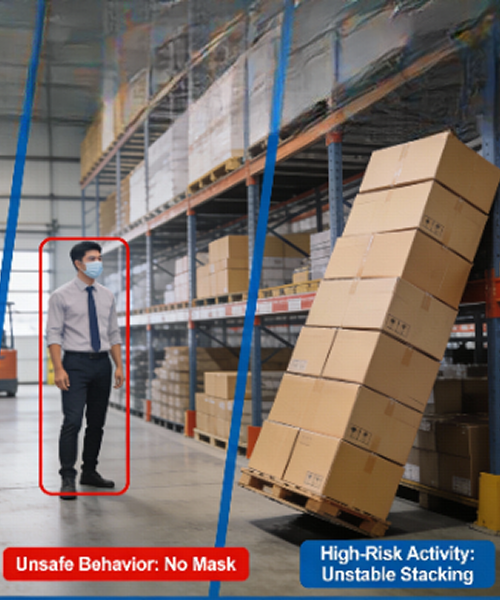

Business Impact

- ✓Reduced workplace accidents and safety violations.

- ✓Improved compliance readiness for audits and inspections.

- ✓Enhanced workforce safety culture across all warehouse zones.

AI-Enabled Workplace Safety Compliance Monitoring System

Ensuring consistent safety compliance across large warehouses was difficult due to manual supervision, limited visibility, and workers overlooking safety procedures. This resulted in increased near-miss incidents, PPE violations, and potential regulatory risks.

The organization deployed an AI-based Safety Procedures Monitoring System that verifies PPE usage, detects unsafe behavior, and identifies high-risk activities. Real-time alerts ensure compliance, reduce workplace hazards, and support a safer operational environment.

- PPE & Safety Compliance Detection

- Unsafe Behavior Monitoring

- Continuous Safety Oversight

Real-Time Forklift Movement Analytics System

The warehouse faced challenges in monitoring forklift routes, preventing collisions, and ensuring safe operation in high-traffic zones. Manual supervision was not sufficient to detect speeding, blind-spot risks, or unsafe maneuvering.

To improve safety and efficiency, the organization installed an AI-enabled Forklift Movement Monitoring System that tracks forklift paths, speed, interactions, and zone entries. The system generates alerts for unsafe driving, congestion, and hazardous movement patterns, reducing accidents and streamlining traffic flow.

- Real-Time Forklift Tracking & Route Analysis

- Unsafe Movement & Speed Violation Alerts

- Collision Risk & Congestion Detection

Business Impact

- ✓Reduced forklift-related incidents and collisions.

- ✓Optimized traffic flow and warehouse routing efficiency.

- ✓Improved operator accountability and safety adherence.