Assembly Quality Control

AI-powered Assembly Line Quality Intelligence enhances production precision by continuously inspecting components, detecting errors, and validating build quality at every stage. The system automatically identifies strip misalignment, missing fuses, incorrect logo placement, and improper nut/bolt/bracket installation with high accuracy. It ensures that even the smallest defects are flagged in real time, preventing faulty products from moving further down the line. Abandoned or foreign objects on the assembly floor are also detected instantly to avoid equipment damage and workflow disruption. With automated inspections and continuous monitoring, manufacturers achieve higher consistency, reduced rework, and improved overall production reliability.

AI-Based Strip Misalignment & Missing Strip Detection System

A high-volume electronics manufacturer struggled with repeated quality defects caused by misaligned or missing strips during assembly. Manual inspection was inconsistent, especially during peak production hours, leading to increased rework and field failures.

To solve this, the facility deployed an AI-powered Strip Detection system that continuously scans every component and instantly identifies misplacement, gaps, or missing strips. The system alerts operators in real time, ensuring defective units are stopped before moving forward. This automation significantly improved build accuracy and reduced scrap generation.

- Real-Time Strip Position Verification

- Automated Defect Flagging

- Consistent Quality Inspection

Business Impact

- ✓Reduced rework and assembly line defects.

- ✓Improved first-pass yield and accuracy.

- ✓Lowered overall inspection time and labor cost.

Business Impact

- ✓Reduced electrical test failures and product recalls.

- ✓Improved assembly reliability and safety compliance.

- ✓Streamlined inspections with automated validation.

Smart Fuse Detection & Assembly Verification System

A large automotive electronics plant experienced frequent issues involving missing or incorrectly placed fuses during assembly, creating safety risks and costly post-production corrections.

The company adopted an AI-driven Fuse Detection solution that identifies fuse presence, positioning, and type accuracy with high precision. The system ensures that every fuse meets quality requirements before advancing down the assembly line and provides instant alerts for mismatches. This improved compliance and reduced failures during electrical testing.

- Accurate Fuse Presence Detection

- High-Precision Component Verification

- Immediate Error Identification

Automated Brand Logo Verification & Placement Accuracy System

Manufacturers faced recurring issues with wrongly placed, missing, or defective logos on products, leading to brand inconsistency and customer dissatisfaction. Manual checks were prone to oversight.

o solve this, the facility integrated an AI-powered Logo Detection system that verifies logo placement, clarity, orientation, and quality for every unit in real time. The system ensures brand uniformity across large production batches and flags any deviation immediately. This helps maintain brand integrity and reduces rework due to cosmetic defects.

- Real-Time Logo Presence & Alignment Check

- High-Precision Visual Quality Control

- Instant Deviation Alerts

Business Impact

- ✓Ensured consistent brand presentation across products.

- ✓Reduced cosmetic defects and repainting work.

- ✓Strengthened product quality and customer trust.

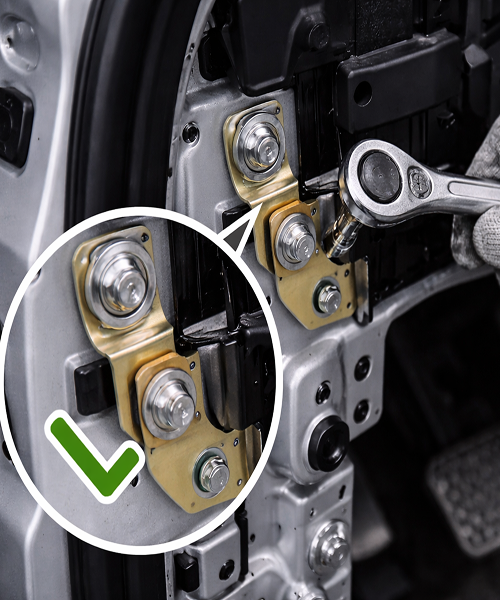

Business Impact

- ✓Reduced mechanical defects and warranty claims.

- ✓Improved assembly uniformity and safety.

- ✓Lowered inspection workload with automated checks.

AI-Driven Nut, Bolt & Bracket Assembly Verification System

Complex mechanical assemblies often suffer from missing, loose, or incorrectly tightened nuts, bolts, and brackets, leading to structural failures and customer complaints. Manual checks are slow and unreliable at scale.

The manufacturer implemented an AI-based Nut/Bolt/Bracket Detection system that verifies the presence, alignment, and correct installation torque visually in real time. The system ensures every mechanical joint is properly assembled before final approval. This enhances structural reliability and prevents costly warranty issues.

- Component Presence & Installation Verification

- Detection of Loose or Misaligned Hardware

- Structural Quality Assurance

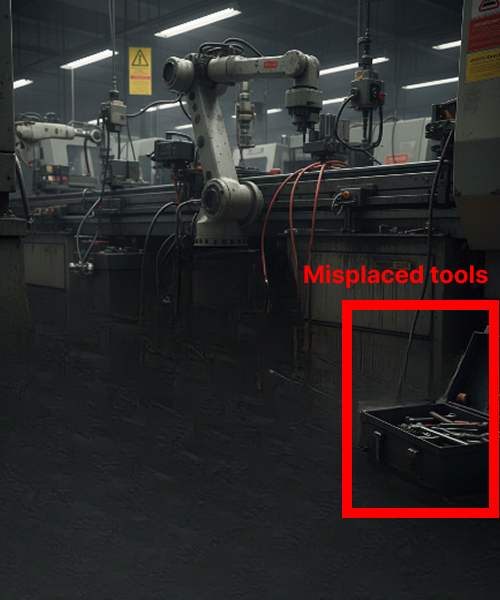

AI-Based Abandoned Object & Foreign Material Detection System

Assembly lines frequently face interruptions and safety risks due to misplaced tools, packaging materials, or abandoned objects left near machines. These lead to equipment damage, downtime, or defective builds. The facility deployed an AI-driven Abandoned Object Detection system that continuously monitors the assembly floor and identifies any foreign or misplaced item instantly.

The system alerts operators before the object becomes a hazard, preventing workflow disruptions and protecting both workers and equipment.

- Real-Time Foreign Object Detection

- Hazard Prevention & Workplace Safety

- Continuous Floor-Level Monitoring

Business Impact

- ✓Reduced line stoppages caused by unwanted objects.

- ✓Prevented equipment damage and safety incidents.

- ✓Enhanced operational continuity and workplace cleanliness.