Manufacturing Safety

Manufacturing Safety uses intelligent video analytics to enhance workplace efficiency and ensure strict safety compliance. The system continuously monitors factory zones to detect intruders or unauthorized access before damage occurs. It identifies worker slip, trip, or fall risks in real time, minimizing injuries and operational downtime. Geo-fencing and zone compliance alerts ensure workers remain within designated safe boundaries. PPE and helmet detection keep safety standards high, while real-time fire, smoke, and hazard alerts protect people and assets. This proactive solution transforms industrial plants into safer, smarter, and more efficient environments.

Intruder & Unauthorized Access Detection System

A large multi-location manufacturing facility struggled with unauthorized entry risks, weak access validation, and manual security checks at sensitive areas. Traditional methods like ID cards, gate logs, and manual supervision failed to detect unknown individuals, allowing potential threats to go unnoticed. These challenges increased safety risks, asset vulnerability, and overall operational inefficiency.

The organization deployed an advanced AI-driven intruder and unauthorized access detection system that uses intelligent cameras to automatically identify unknown persons, verify authorized individuals, and trigger instant alerts. The system monitors restricted zones in real time and prevents unauthorized access before incidents occur—ensuring stronger security.

- Proactive Intruder Identification

- Enhanced Access Validation

- Improved Safety & Asset Protection

Business Impact

- ✓Significantly reduced unauthorized entry incidents, strengthening facility-wide security.

- ✓Minimized manual security checks, lowering operational costs.

- ✓Improved safety compliance and asset protection through real-time zone.

Business Impact

- ✓ Reduced workplace fall incidents, improving staff safety and morale.

- ✓ Lowered downtime and medical claim costs through early detection.

- ✓ Strengthened compliance reporting with automated incident data logs.

Real-Time Worker Fall Prevention & Safety Analytics

A major industrial manufacturing plant faced recurring worker slip, trip, and fall incidents across production floors and loading zones. Manual supervision could not track unsafe movements or spot risky floor conditions in real time, leading to frequent injuries and unplanned downtime. Inaccurate incident reporting and delayed response times also increased operational costs, compliance issues, and workforce safety concerns across multiple sites.

To overcome this, the organization implemented an AI-powered Worker Slip/Trip/Fall Prevention system using VAMS . The technology continuously monitors worker posture, movement, and walking paths to detect slips, loss of balance, sudden falls, and near-miss events. Real-time alerts allow supervisors to respond immediately, prevent injuries.

- Real-Time Slip/Trip/Fall Event Detection

- Posture & Movement Monitoring Analytics

- Proactive Hazard Identification & Alerts

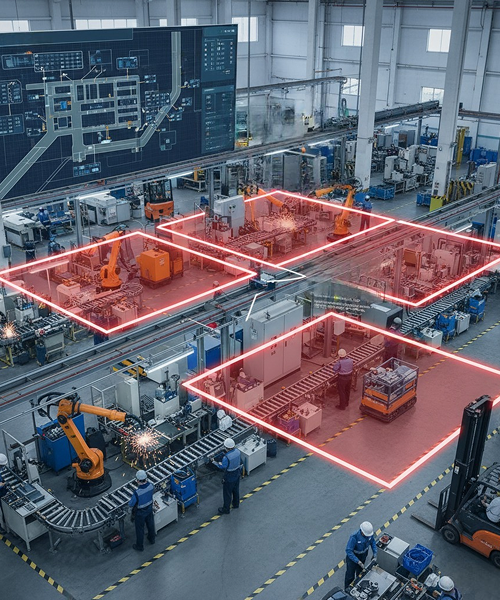

AI-powered Geo-fencing & Zone Compliance System

A large manufacturing facility struggled to maintain zone restrictions and worker movement compliance across production areas, hazardous zones, and storage units. Manual supervision and ID-based checks were ineffective, making it difficult to detect boundary violations, ensure operational discipline, and control access to high-risk sections.These lapses frequently resulted in safety breaches, workflow interruptions, and avoidable accidents.

The organization implemented an AI-powered Geo-fencing & Zone Compliance System using VAMS. The system creates virtual boundaries inside the plant and continuously tracks worker location and movement patterns. It instantly alerts supervisors when unauthorized movement into restricted areas occurs, helping enforce discipline, reduce risk exposure, and maintain operational workflow integrity.

- Virtual Zone Boundary Monitoring

- Unauthorized Area Movement Alerts

- Better Workforce Discipline & Compliance

Business Impact

- ✓Reduced zone violation incidents and workplace accidents.

- ✓Increased operational discipline and workflow consistency.

- ✓Stronger compliance reporting with automated violation logs.

Business Impact

- ✓Increased PPE compliance across all shifts and zones.

- ✓Significant reduction in workplace injuries and violations.

- ✓Improved safety audit readiness and regulatory confidence.

AI-enabled PPE Mask & Helmet Compliance System

The organization faced continuous safety compliance challenges due to inconsistent use of personal protective equipment such as helmets, masks, and safety vests. Manual checks were time-consuming and unreliable, making it impossible to verify compliance across multiple shifts and large workforce groups. This increased injury risk, regulatory non-compliance, and operational liability.

To resolve these issues, the facility adopted an AI-driven PPE Mask/Helmet Detection System that uses video analytics to detect workers entering operational areas without mandatory safety gear. The platform automatically alerts supervisors, restricts non-compliant entry, and generates digital safety audit trails—establishing a safer and more disciplined work culture.

- Helmet & Mask Detection for Safety Compliance

- Entry Restriction for Non-Compliant Workers

- Automated Digital Safety Audit Logs

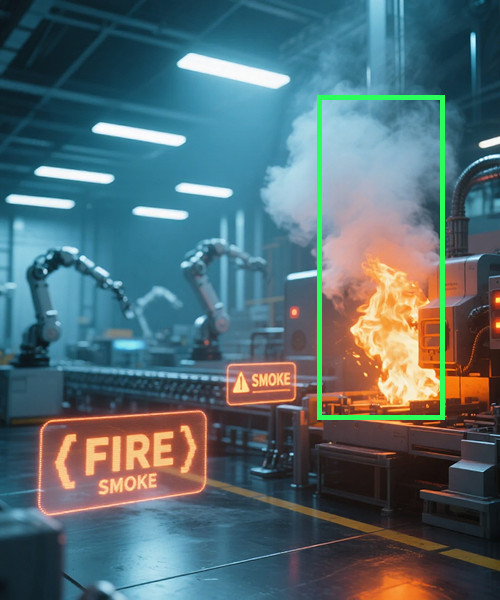

AI-based Fire & Smoke Early Warning System

The manufacturing plant had limited fire safety visibility due to delayed smoke detection, manual alarm triggers, and traditional sensor-only fire systems. These limitations slowed emergency response, increased damage risk, and put worker lives and assets in danger—especially in high-temperature production environments.

To strengthen industrial fire safety response, the organization implemented an AI-based Fire & Smoke Hazard Detection System driven by video intelligence. The solution continuously analyses live camera feeds to identify early smoke signatures, sudden flame visibility, and hazardous heat zones—triggering instant alerts and guiding faster evacuation and response actions.

- Early Video-based Smoke & Flame Detection

- Instant Alerts for Rapid Emergency Response

- Continuous Hazard Monitoring Across Facilities

Business Impact

- ✓Prevented major fire incidents through early warning detection.

- ✓Reduced asset damage and unplanned production downtime.

- ✓Enhanced workplace safety confidence and emergency preparedness.